Screw diameter: 65mm

Screw L/D Ratio: 22

Shot Volume: 1174 cm³

Shot weight(PS): 1068g

Injection Rate: 331cm³/s

Injection Pressure: 182Mpa

Screw Speed: 192 rpm

Warranty: 2 years

Voltage: 380V/ 50HZ/ 3PHASE, 440V/ 50HZ (60HZ) / 3PHASE, 220V/ 60HZ/3PHASE

Commisioning and Training, Installation service available.

Technical Data Specification

| Specifications | Unit |

350Ton |

||

| INJECTION UNIT | A | B | C | |

| Screw diameter | mm | 60 | 65 | 70 |

| Screw L/D ratio | L/D | 23 | 22 | 20 |

| Theoretical shot volume | cm3 | 1000 | 1174 | 1362 |

| Shot weight(PS) | g | 910 | 1068 | 1156 |

| Injection pressure | Mpa | 214 | 182 | 157 |

| Max. screw speed | rpm |

192 |

||

| CLAMPING UNIT | ||||

| Clamping force | kN | 3500 | ||

| Opening stroke | mm | 670 | ||

| Distance between tie-bars | mm | 730 x 670 | ||

| Max. mold height | mm | 680 | ||

| Min. mold height | mm | 250 | ||

| Ejector stroke | mm | 160 | ||

| Ejector force | kN | 70 | ||

| OTHERS | ||||

| Drive power | kW | 49 | ||

| Heating capacity | kW | 22.8 | ||

| Machine dimensions | m | 6.9 x 1.9 x 2.35 | ||

| Machine weight | t | 14 | ||

Servo Energy-saving Injection Molding Machine Characteristic

Servo Energy-saving Plastic Injection Molding Machine

Injection Molding Machine Related Industry:

Automotive Industry |

Electronic Industry |

Home Appliance Industry |

Packaging Industry |

Daily Commodity |

Stationery/Toy Industry |

Medical Industry |

Construction Industry |

|

◉Full supported injection base, avoid it up and down during high pressure injection. ◉Optional screw designs for different material processing applications. ◉Dual carriage cylinders improve a better injection precision. ◉Injection unit steel pipes adopt pipe fitting to connect, no welding design ensure maintenance and after-sale service to be easier. ◉Imported high quality SKD61 screw tip, check ring and thrust ring, 38CrMoAl screw and barrel. ◉Injection guiding bushes adopt graphite-cooper material; ensure high repeatability precision and long life. ◉Centralized lubrication for injection unit, easy for feeding lubrication grease. ◉Barrel PID controls the difference of temperature less error. ◉Safety chains for high pressure hoses can prevent hoses hurt people. |

|

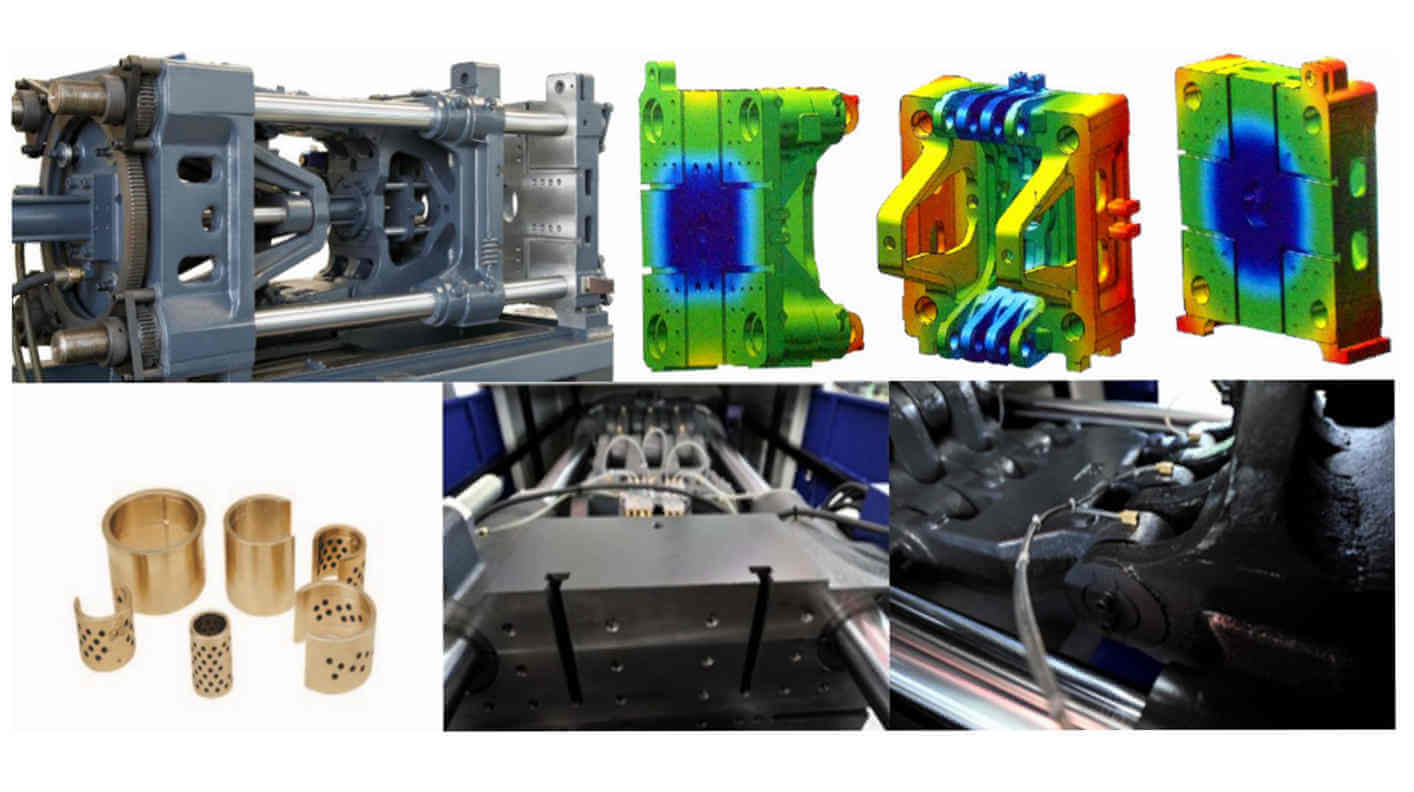

Five point Box-type mold platen design, strong and reliable. ◉Linkage structure of front connecting rod increase strength greatly as well as whole clamping unit’s rigidity and accuracy. ◉Up-grade Tie-bar material and Toggle pin adopt 42CrMo material with high frequency induction hardening processing technology, working life much longer. ◉High quality copper bushes on tie bars guiding parts, working life longer. ◉Push platen adopts the self-lubrication copper bushes, long life, high speed & precision. ◉Thicken central of platen, effective for mold and machine life and product precision. ◉Enhanced strength for fixed platen, improve products stability and quality. ◉Special designed machine base, clamping unit supported by the base girder, ensure machine base perfect balance, and few deformation after long time working. |

|

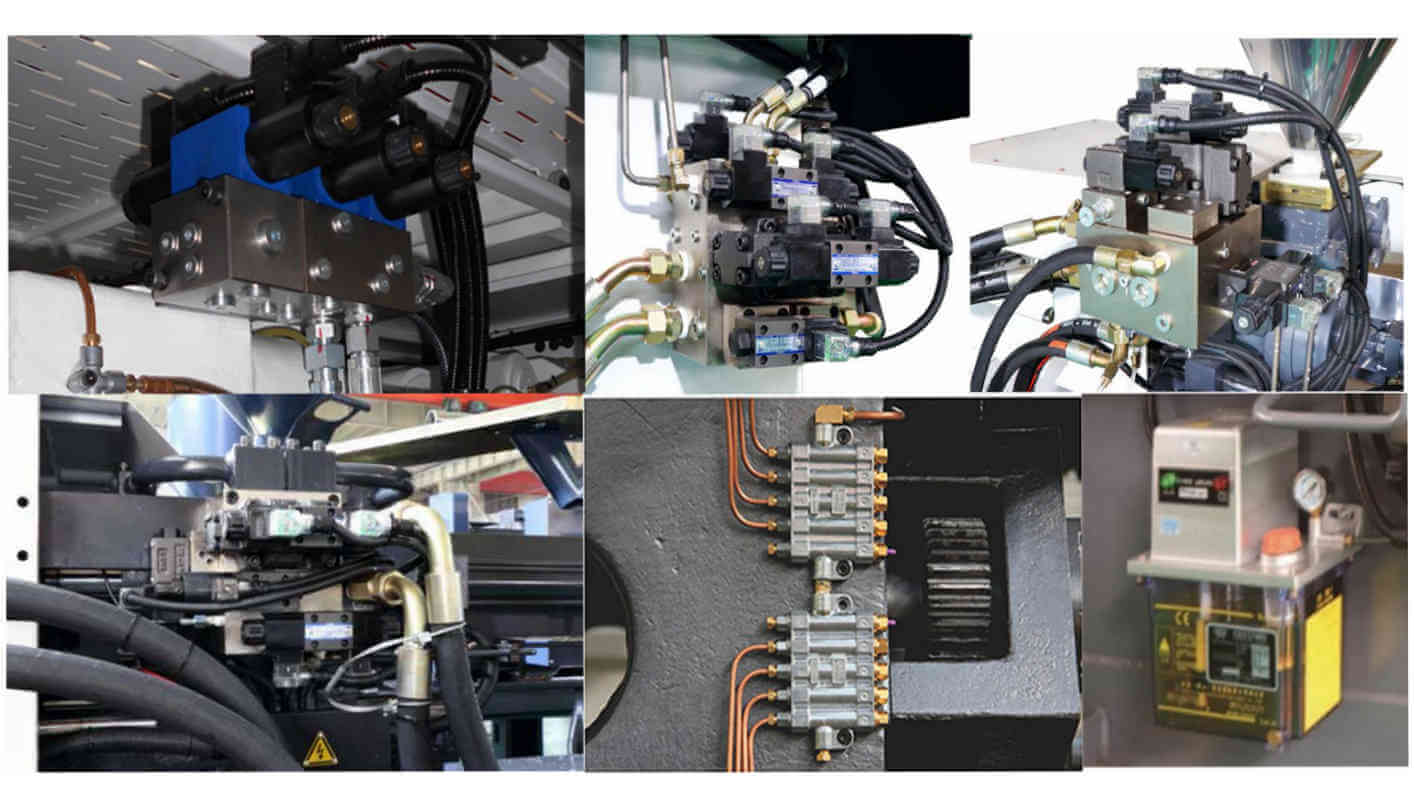

◉World famous brands hydraulic parts ensure machine’s stability and fast response. ◉Adopt modular adaptor valve blocks, come true change different drive system easier. ◉Standard with self-seal suction filter, easy for maintenance. ◉Modular designed Advanced & fast response hydraulic circuit, response speed raise 25%. ◉Germany DIN standard hydraulic pipe fittings with seal, G screw thread style plug, ensure no leaking and avoid oil pollution. |

|

◉Five point Box-type mold platen design, strong and reliable. ◉Linkage structure of front connecting rod increase strength greatly as well as whole clamping unit’s rigidity and accuracy. ◉Up-grade Tie-bar material and Toggle pin adopt 42CrMo material with high frequency induction hardening processing technology, working life much longer. ◉High quality copper bushes on tie bars guiding parts, working life longer. ◉Push platen adopts the self-lubrication copper bushes, long life, high speed & precision. ◉Thicken central of platen, effective for mold and machine life and product precision. ◉Enhanced strength for fixed platen, improve products stability and quality. ◉Special designed machine base, clamping unit supported by the base girder, ensure machine base perfect balance, and few deformation after long time working. |

Shipping and Transportation